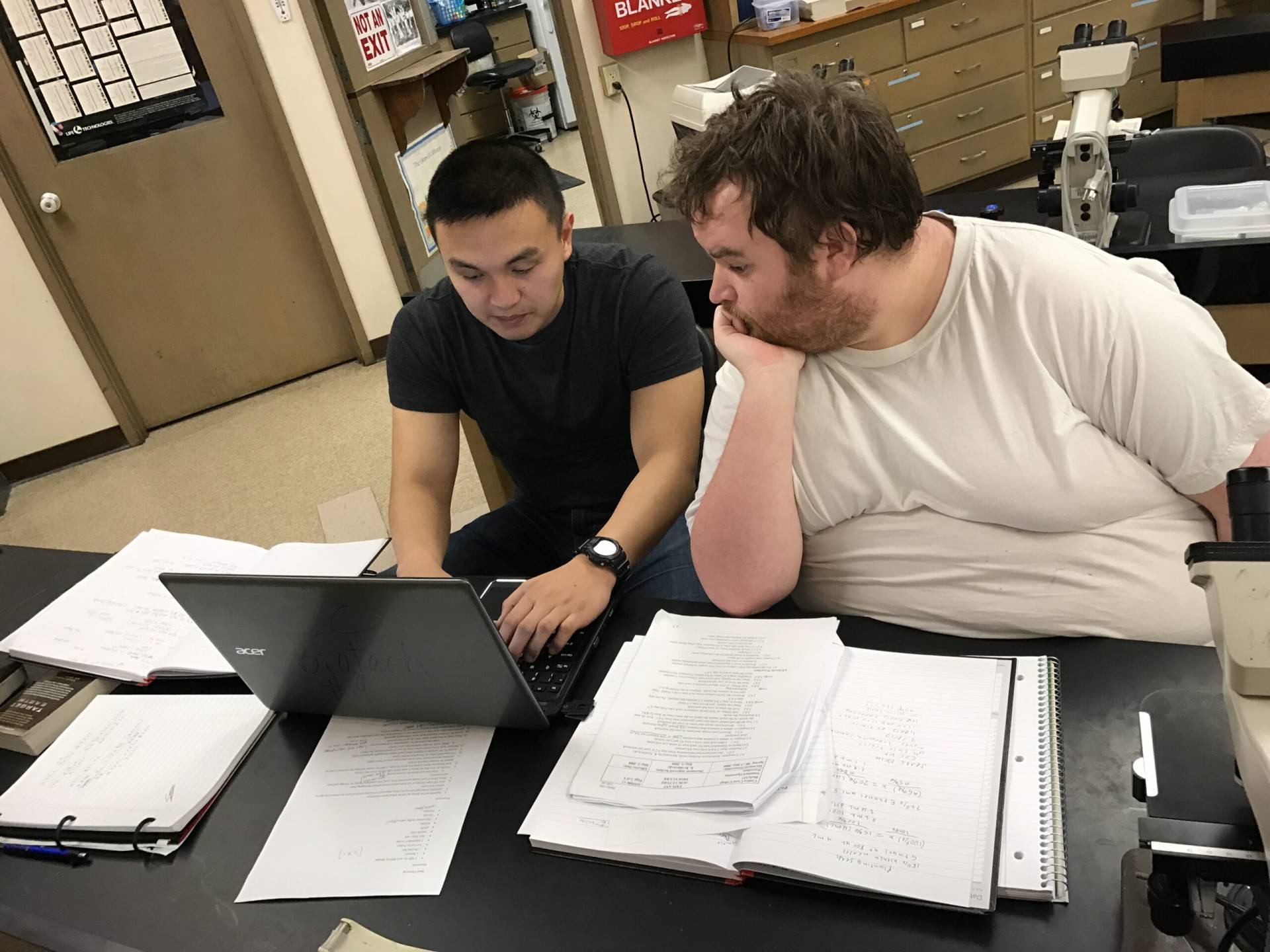

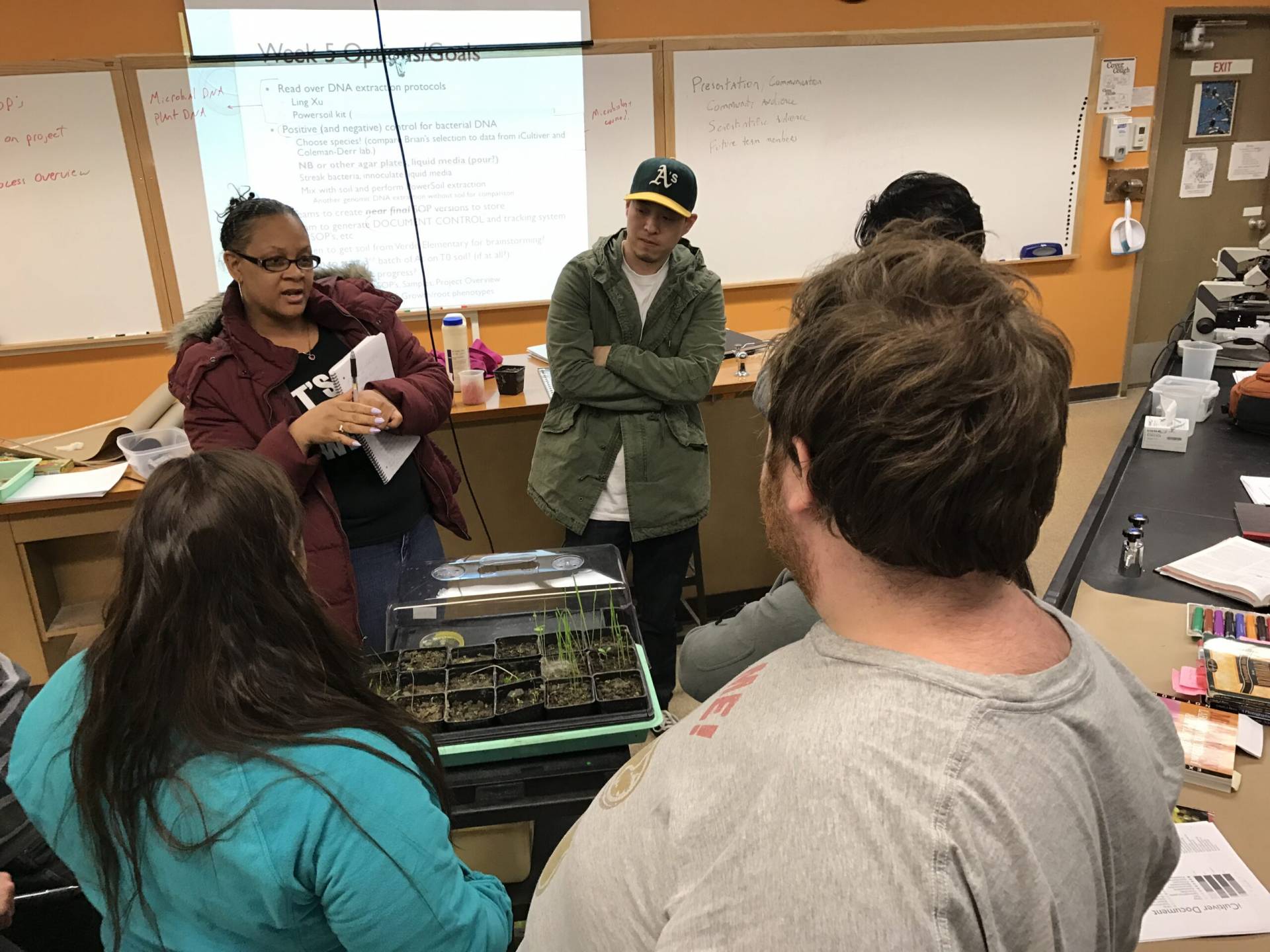

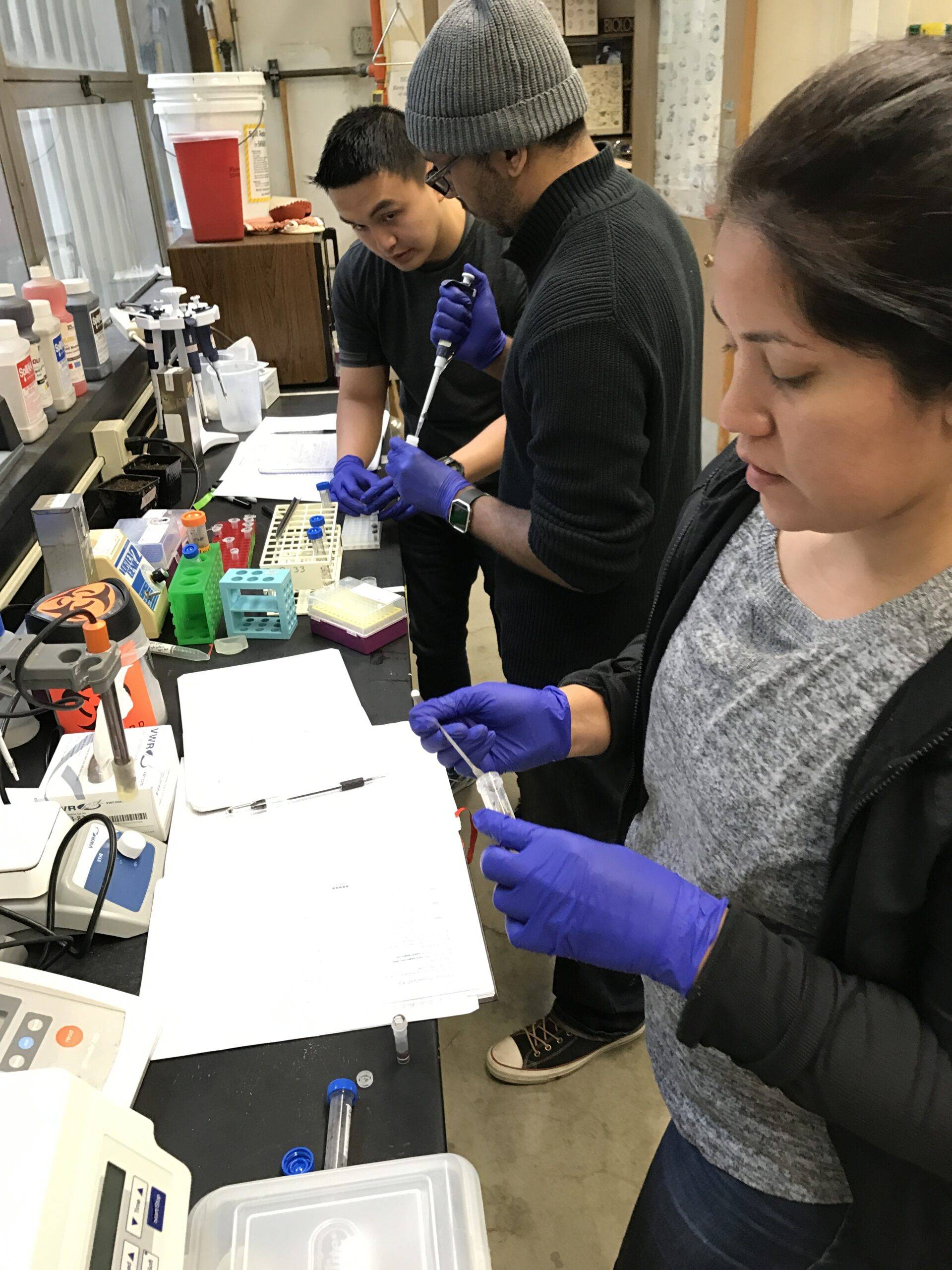

BIOSC188 (or BIOSC888N): This course will develop foundational knowledge of the key functions within biotechnology operations: project management, supply chain management, product development, oversight and compliance, production, packaging and documentation, quality assurance/control, and customer satisfaction. The roles and responsibilities of these functions in an analytical lab environment will be explored. This course will provide extensive hands-on experience in the development, production, and delivery of products and reports for use by both internal and external customers. Specifically, students in this course practice scientific sampling and analysis techniques, documentation practice, using quality systems in the workplace, scientific thinking, and effective communication while performing work as a member of an analytical laboratory team. Standards of Good Manufacturing Practice and effective communications with stakeholders will be emphasized as students improve their workplace skills important in life science industries such as biotechnology and biomedicine.

Skills in

- Project management (including timely preparation of deliverables)

- Quality Assurance, including building quality systems

- Documentation (notebook, batch records, data logs)

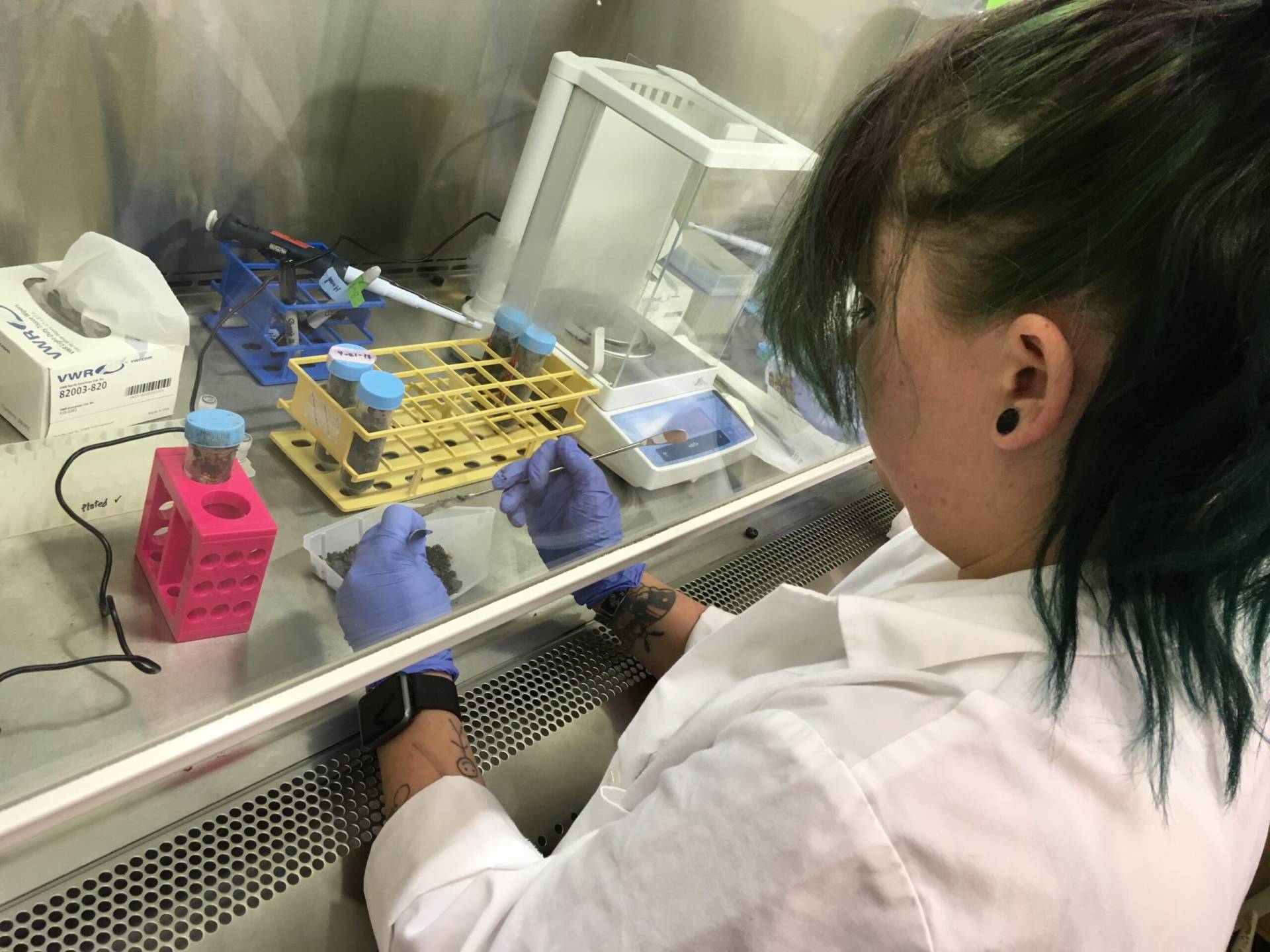

- Sampling and labeling

- Common laboratory equipment

- operational roles and responsibilities in the life science industry, including teamwork, effective commnication, and timely preparation of deliverables

- Validation

- Staffing for manufacturing

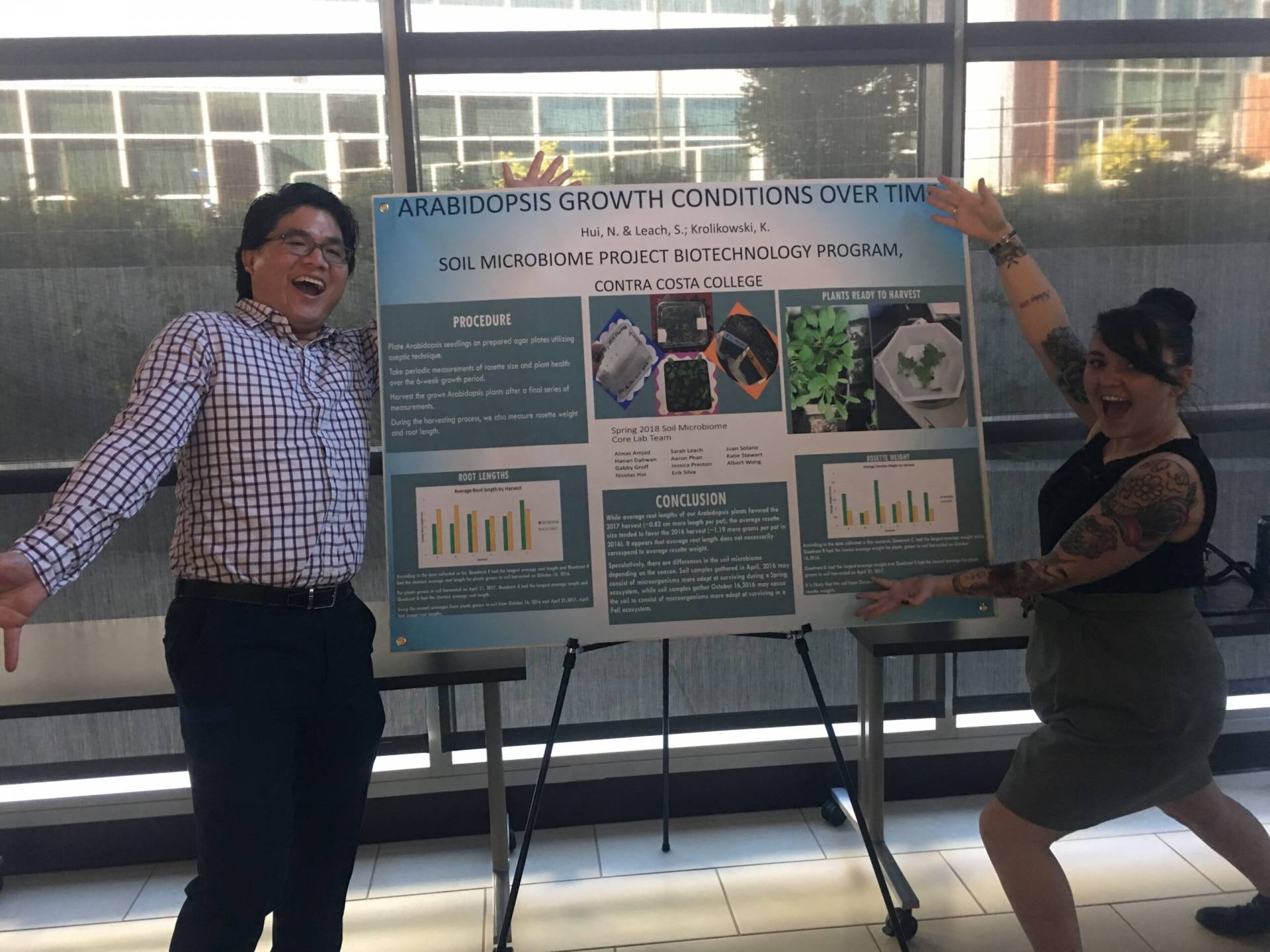

- Product development

Knowledge of

- Bioinformatics

- Microbiology

- Agronomic traits and measurements

- Quality systems amd concepts important for life science industries, including product development, project management, production, supply chain management, quality control, quality assurance, validation, documentation, and compliance with standards

- Customer service (internal and external)

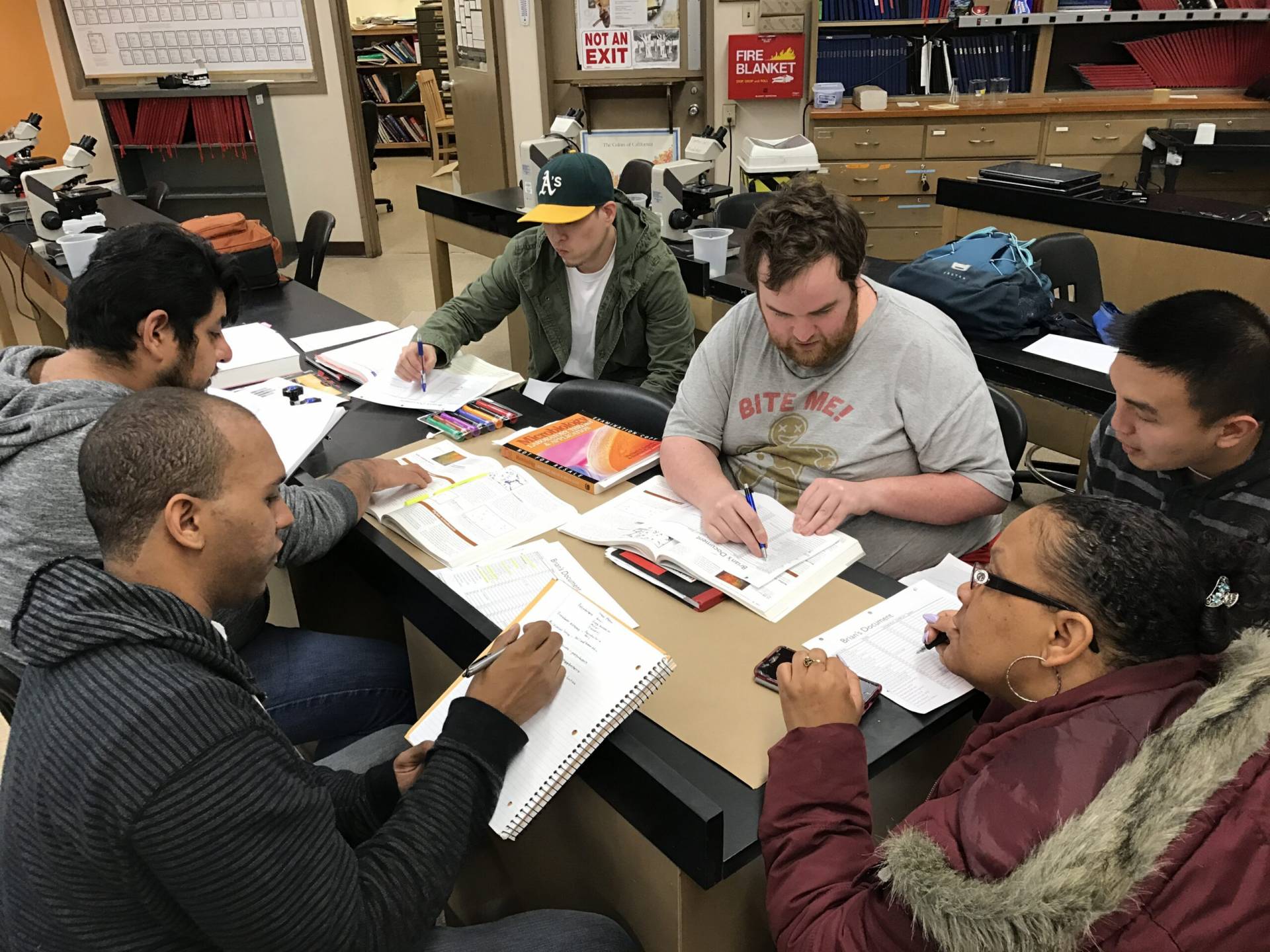

- Team dynamics

- Scientific process and analysis, inlcuding experimental design

- Sample data and storage

- Aseptic technique

- oversight and compliance

Ability to

- Continuous improvement

- Communication and teamwork

- Supply chain management (including demand forecasting, production scheduling, and inventory management)

- Communicate objectives and results of work using both written and spoken language

- Quality control, including sampling, testing, and statistical methods

- Uprstream processes

- Downstream processes

- Fill and finish processes

What types of jobs does it prepare for?

- Compliance Specialist

- Product development associate

- Validation specialist

Core Competencies

- Recognize when information is necessary and respond to appropriate personnel

- Notice errors in technical documents, changes suggested

- Inefficiencies recognized, communicated, continuous improvement occurs

- Adaptable and willing to learn on the fly (change is fast in the industry)

- Speak-up culture, critical thinking (ID when wrong and have courage to speak up)

- What are you doing (this technique), and why are you doing it? Why is what you are doing important? (technical sense of the ‘care’ of the step, and Information gained by the technique for the project)

- Able to work in both directive-driven and in consensus-driven environments